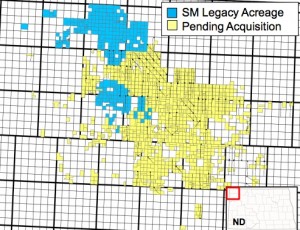

Whiting Petroleum reported record Bakken/Three Forks production of 80,195 boe/d in the second quarter of 2014. The data was released in the company's second quarter report, and represents a 33% increase in production year-over-year. Bakken/Three Forks production counted for 73% of the company's total production across its portfolio. Currently the company holds 1,059,957 gross (674,162 net) acres in the Williston Basin in North Dakota and Montana. Whiting Petroleum recently announced the acquisition of Kodiak Oil & Gas, in an all stock transaction, for $3.8 billion. The deal makes the combined company the largest Bakken/Three Forks producer, unseating Harold Hamm’s Continental Resources from the top spot.

Read more: Whiting Petroleum Acquires Kodiak Oil & Gas - $3.8 billion

“Whiting CEO James Volker said in a prepared statement, “we believe we have plenty of running room in theWilliston Basin, particularly in light of our new completion techniques and downspacing programs.”

Whiting Bakken Well Completions Benefiting from Cemented Liners

According to company officials, recent results using cemented liner completions in Whiting's Hidden Bench field have been particularly strong. The 11 wells completed in the second quarter using cemented liners had an average initial production (IP) rate of 2,872 boe/d, a 50% increase over the average of the company's Hidden Bench wells completed with sliding sleeve technology.

Whiting Bakken First Slickwater Frac Job

Whiting's first slickwater frac job, the Sundheim 21-27-1H well at the company's Missouri Breaks field in McKenzie County, North Dakota, was completed on August 24, 2013. It had a 120-day production rate of 374 boe/d, which was 44% greater than an offsetting well, which was completed using an uncemented liner and sliding sleeve technology. Currently the company has 11 slickwater fracs either underway or planned for the third quarter of 2014 at the Missouri Breaks, Sanish, Hidden Bench and Pronghorn fields.

Read more at whiting.com